Grouting Joints and Lateral Connections

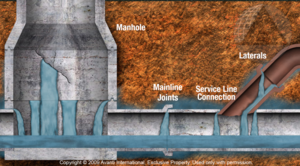

There are multiple potential points of failure where leaks can begin.

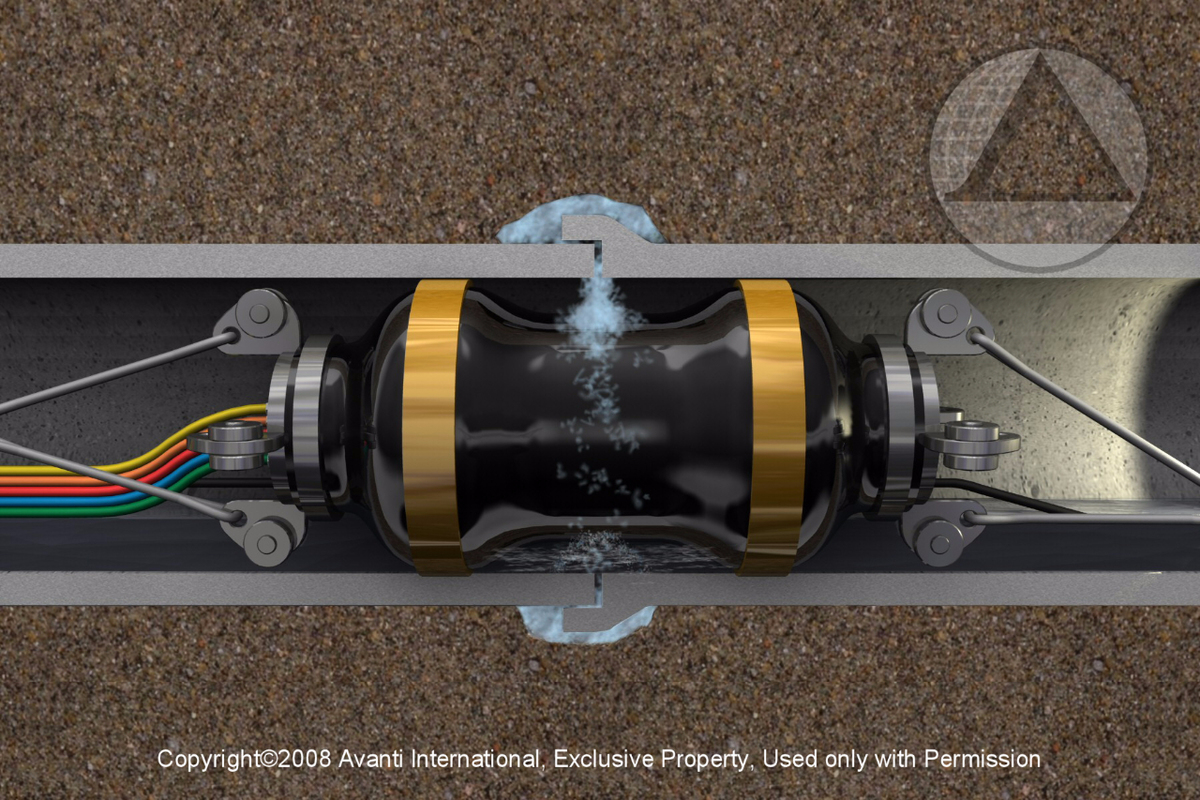

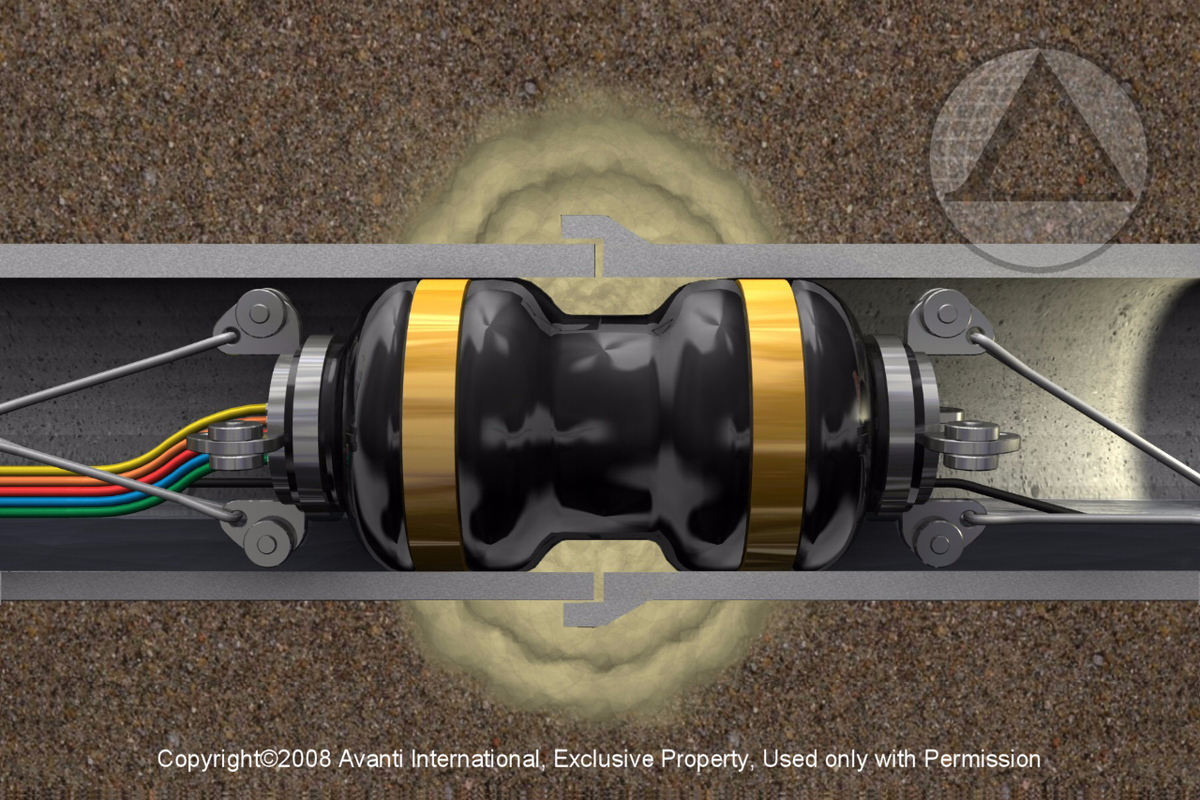

The main packer is positioned at the leaking joint.

Grouting is injected into the area.

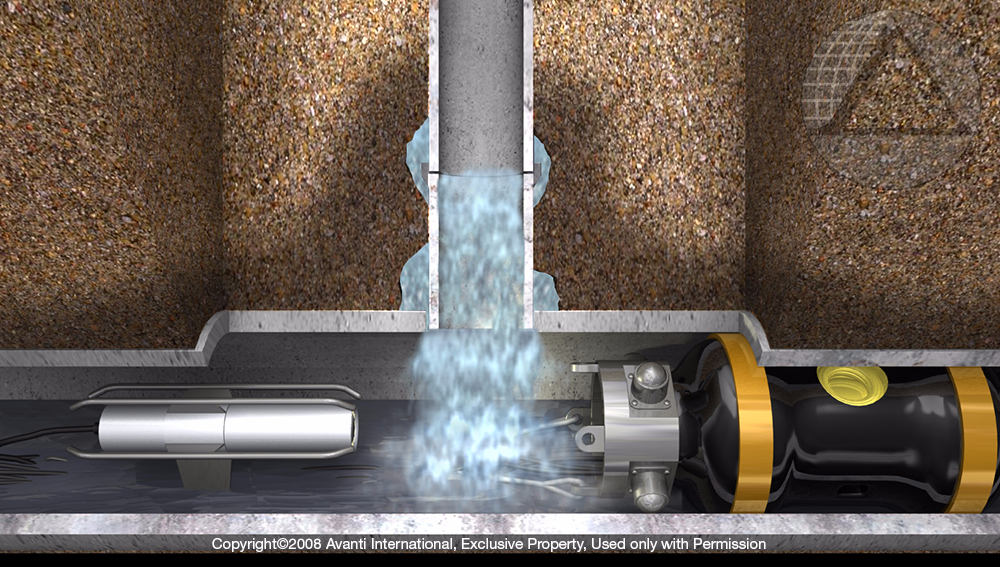

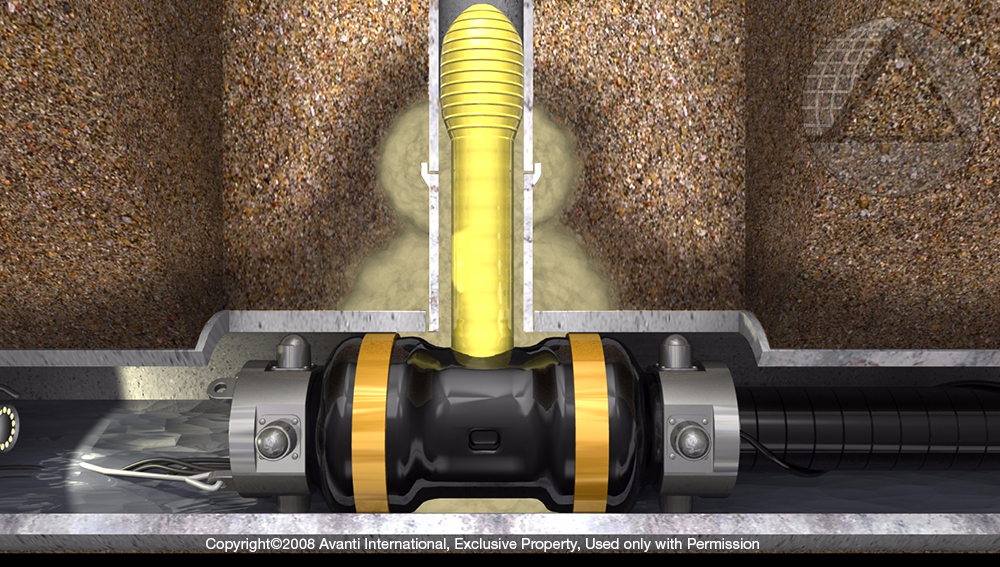

Laterals are also common sources for leaks.

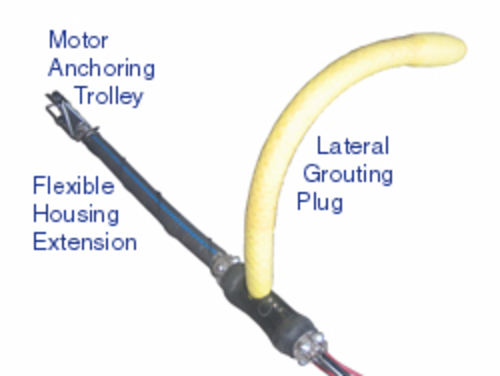

The lateral packer is positioned at the pipe connection and grout is injection to stop infiltration.

|

Many Municipalities struggle with infiltration into the sewer system increasing the overall treatment costs. Most infiltration enters the sewer system through joints, manholes and the first few feet of the service connection. The best and most economical way to stop leaks is through chemical grouting. Nieltech has the technology required to perform this service.

Nieltech uses experienced and trained grout technicians to seal any leaking joints, service connections, manholes, and storm drains. Even though leaking joints may not be visible to the CCTV camera, it can be easily detected by our Packer Testing System. Using air, the packer can determine the integrity of a joint before the leak becomes visible. Nieltech uses the injection packer to complete the joint pressure testing to identify any leaking joints that may not be visible to the eye. Once identified the injection packer is used to grout the joint and air test it.

Since the first few meters of the lateral connection to the main line is situated under the water table, studies have shown that Service Laterals are also often significant sources of infiltration. The most economical and effective way to stop these leaks is through the same chemical grouting process. Nieltech has the latest lateral injection technology with the capability of sealing lateral connections at the main as well as a few feet up the connection without the need for a cleanout at property line. A CCTV inspection of the entire test and sealing process is recorded for later viewing and verification. The right tool for the right job.

|

|||||||||||||

|

||||||||||||||